- Home

- Furnace/ Equipment

- Melting and Holding Furnaces

- Fixed Melting and Holding Furnace

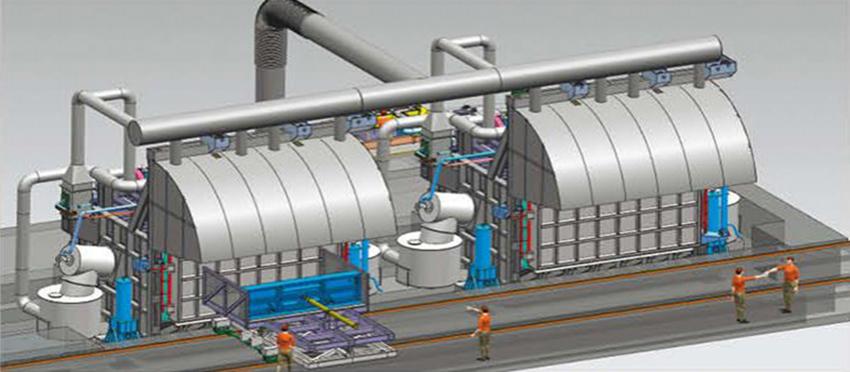

Fixed Melting and Holding Furnace

ApplicationFixed melting and holding furnace mainly used in smelting of aluminum alloy or heat preservation for molten aluminum as it has good sealing property.

Fixed melting and holding furnace can perform combustion with four types of fuel such as natural gas, liquefied petroleum gas, heavy oil and diesel. The furnace body is fixed and non-movable. It has straight furnace door indicating the door can be moved vertically which is convenient and easy to use. Slanting furnace door indicates the door does not lift or lower vertically but it is shut tightly sorely by the weight of the furnace door. This helps to reduce the heat energy lost. Fixed melting and holding furnace mainly consists of steel external shell, refractory lining, furnace door, lifting and clamping mechanism of the furnace door and burner system. The fixed melting and holding furnace can be equipped with auxiliary equipment such as electromagnetic stirrer, molten aluminum pump, charging car, etc. This model of furnace uses regenerative burner system as burner which emits 90% and above of the waste gas after heat exchanges through the regenerative bed. Other waste gas emitted via conventional exhaust channel which saves energy.

Parameters- Production: 5 tons- 60 tons

- Furnace door type: straight furnace door

- Melting rate: 2-8 tons of aluminum per hour

- Air pressure: 65-100kPa

- Temperature accuracy: ±5℃

- Fuel consumption: 52meter cube/ tons*aluminum

- Highest working temperature: 1050℃

- Highest control temperature: 1100℃

- Production: 5 tons- 60 tons

- Furnace door type: straight furnace door

- Melting rate: 2-8 tons of aluminum per hour

- Air pressure: 65-100kPa

- Temperature accuracy: ±5℃

- Fuel consumption: 52meter cube/ tons*aluminum

- Highest working temperature: 1050℃

- Highest control temperature: 1100℃

- Smaller energy consumption, lowest fuel consumption reaches 52meter cube/ tons*aluminum (Calculated based on natural gas)

- Implement regenerative burner system, low temperature of the waste gas which is about 250℃ and hence reducing the heat carried away from the furnace. Energy lost is minimized.

- It controls the temperature with thermocouple discontinuous temperature measurement. Fire power is adjusted automatically which achieve the purpose of energy saving.

- It is shut tightly by the weight of the furnace door, simple structure, easy maintenance.

- Bricklaying with strong refractory materials which is applicable in any furnace type and any alloy smelting.

- Easy and convenient for maintenance, low maintenance cost. More suitable for economical furnace type. The economical furnace has smaller tonnage. For example, aluminum melting furnace with volume 10 tons and below is suitable with brick liner.

- The better the mixing of the refractory lining, the longer the lifespan of the bricklaying structure.

- Using non-adhesive aluminum castable or strong strength cement castable. As such, the furnace has excellent sealing property and therefore the overall heat preservation of the furnace is guaranteed. Heat energy lost is minimized.

Example of industrial furnace

Foshan Nanhai Huitai Technology Machine Co., Ltd.

Tel: +86-757-86687030

+86-757-86687027

Fax:+86-757-86687029